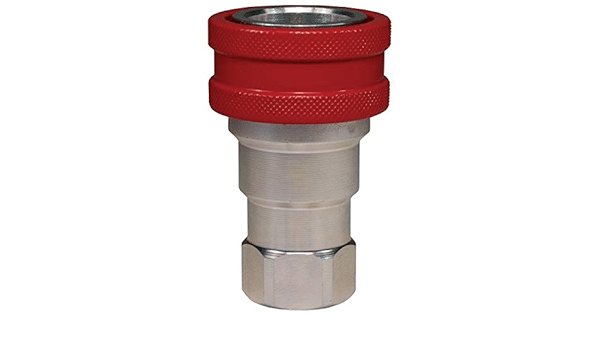

Dixon 3HF3-BOP Blowout Preventer

Dixon 3HF3-BOP Blowout Preventer

Product Description :

- It is a critical safety device used in oil and gas drilling operations to prevent uncontrolled releases of oil or gas from a well. It is designed to withstand high pressures and provide a secure seal to prevent blowouts, which can lead to catastrophic accidents, environmental damage, and loss of life.

- They are activated using hydraulic systems and can be operated remotely. Regular testing and maintenance are crucial to ensure their functionality.

- Steel coupler sleeves are hardened to resist deformation and maximize service life. Valve seals are crimped in place to maintain integrity during excessive flow conditions and pressurized connection.

-

A blowout preventer (BOP) is a critical safety device used in oil and gas drilling operations to prevent uncontrolled release of formation fluids from a well. It seals the wellbore during drilling, protecting personnel, equipment, and the environment from blowouts.

-

BOPs are manufactured from high-strength steel and corrosion-resistant alloys, designed to withstand extreme pressures, temperatures, and harsh drilling conditions. They are available in various configurations, including annular, ram-type, and hydraulic-actuated models, to suit different well requirements.

-

Blowout preventers are widely used in onshore and offshore oil and gas drilling rigs, ensuring safe operations, regulatory compliance, and reliable well control.

Product Specification :

| Material |

Steel

|

|---|---|

| Maximum OD |

1.41″ (35.8 mm)

|

| Thread |

Female NPTF

|

| Seal |

FKM

|

| Body Size |

3/8″

|

| Burst Pressure |

16,500 PSI

|

| Thread Size |

3/8″ – 18

|

| Length |

2.50″ (63.5 mm)

|

| Hex |

7/8″

|

| Flow |

12 GPM

|